TROY, Mich., Jan. 8, 2019 /PRNewswire/ -- Meritor, Inc. (NYSE: MTOR) today announced it has 22 electrification programs with global OEMs that is expected to put at least 130 fully electric medium- and heavy-duty commercial trucks on the road through 2020.

"These emission-free solutions offered under Meritor's Blue Horizon technology brand have the potential to transform the industry by meeting the rising global demand for clean, electric-powered drivetrains that we believe will deliver a high-efficiency solution that greatly reduces the total cost of ownership for our customers," said John Bennett, vice president and chief technology officer for Meritor. "These programs position Meritor for future growth in an emerging industry segment."

In the first half of 2019, a major fleet customer will begin operating the first of six medium-duty Peterbilt Model 220EV Class 6 pick-up and delivery trucks equipped with Meritor's 14Xe electric drive systems and fully integrated subsystems from TransPower, a leader in electrification technologies for large commercial vehicles. In 2017, Meritor announced a strategic investment in TransPower.

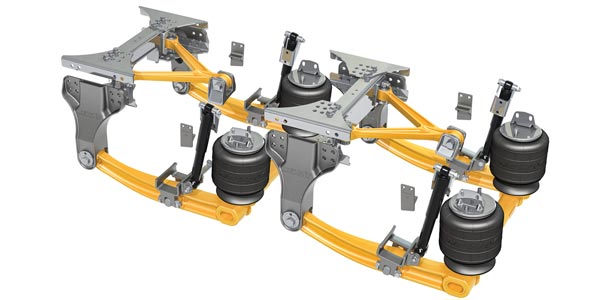

Meritor's eCarrier platform integrates an electric motor into the axle, freeing up space for batteries and other components. This flexible design is the foundation for various drivetrain configurations, including full electric, hybrid and single or tandem axles with various options based on product application for vehicle Classes 5 through 8.

Among the 130 commercial vehicles expected to be placed into service by 2020, 60 of these trucks received funding from the California Air Resources Board as part of a broader effort to reduce carbon emissions in freight facilities.

In addition to the truck applications, a prototype school bus outfitted with Meritor and TransPower electrification solutions has been exceeding expectations during testing in Escondido, California since late May. Testing includes climbing steep grades, stop-and-go at low speeds, off-road and freeway driving as well as heavy-load hauling on rural roads.

"Several large customers have come out to see and ride the bus, and their comments are very complimentary from ride comfort, noise, vibration and harshness, acceleration, top speed and design simplicity standpoints," Bennett said.

About Meritor

Meritor, Inc. is a leading global supplier of drivetrain, mobility, braking and aftermarket solutions for commercial vehicle and industrial markets. With more than a 100-year legacy of providing innovative products that offer superior performance, efficiency and reliability, the company serves commercial truck, trailer, off-highway, defense, specialty and aftermarket customers around the world. Meritor is based in Troy, Mich., United States, and is made up of approximately 8,600 diverse employees who apply their knowledge and skills in manufacturing facilities, engineering centers, joint ventures, distribution centers and global offices in 19 countries. Meritor common stock is traded on the New York Stock Exchange under the ticker symbol MTOR. For important information, visit the company's website at www.meritor.com.

Forward-Looking Statement

This release contains statements relating to future results of the company (including certain projections and business trends) that are "forward-looking statements" as defined in the Private Securities Litigation Reform Act of 1995. Forward-looking statements are typically identified by words or phrases such as "believe," "expect," "anticipate," "estimate," "should," "are likely to be," "will" and similar expressions. Actual results may differ materially from those projected as a result of certain risks and uncertainties, including but not limited to reliance on major OEM customers and possible negative outcomes from contract negotiations with our major customers, including failure to negotiate acceptable terms in contract renewal negotiations and our ability to obtain new customers; the outcome of actual and potential product liability, warranty and recall claims; our ability to successfully manage rapidly changing volumes in the commercial truck markets and work with our customers to manage demand expectations in view of rapid changes in production levels; global economic and market cycles and conditions; availability and sharply rising costs of raw materials, including steel, and our ability to manage or recover such costs; our ability to manage possible adverse effects on our European operations, or financing arrangements related thereto following the United Kingdom's decision to exit the European Union or, in the event one or more other countries exit the European monetary union; risks inherent in operating abroad (including foreign currency exchange rates, restrictive government actions regarding trade, implications of foreign regulations relating to pensions and potential disruption of production and supply due to terrorist attacks or acts of aggression); risks related to our joint ventures; rising costs of pension benefits; the ability to achieve the expected benefits of strategic initiatives and restructuring actions; our ability to successfully integrate the products and technologies of Fabco Holdings, Inc. and AA Gear Mfg., Inc. and future results of such acquisitions, including their generation of revenue and their being accretive; the demand for commercial and specialty vehicles for which we supply products; whether our liquidity will be affected by declining vehicle production in the future; OEM program delays; demand for and market acceptance of new and existing products; successful development and launch of new products; labor relations of our company, our suppliers and customers, including potential disruptions in supply of parts to our facilities or demand for our products due to work stoppages; the financial condition of our suppliers and customers, including potential bankruptcies; possible adverse effects of any future suspension of normal trade credit terms by our suppliers; potential impairment of long-lived assets, including goodwill; potential adjustment of the value of deferred tax assets; competitive product and pricing pressures; the amount of our debt; our ability to continue to comply with covenants in our financing agreements; our ability to access capital markets; credit ratings of our debt; the outcome of existing and any future legal proceedings, including any proceedings or related liabilities with respect to environmental, asbestos-related, or other matters; possible changes in accounting rules; and other substantial costs, risks and uncertainties, including but not limited to those detailed in our Annual Report on Form 10-K for the year ended September 30, 2018, as amended and from time to time in other filings of the company with the SEC. These forward-looking statements are made only as of the date hereof, and the company undertakes no obligation to update or revise the forward-looking statements, whether as a result of new information, future events or otherwise, except as otherwise required by law.